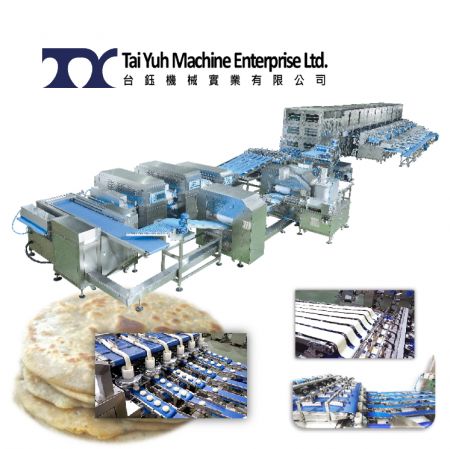

Chinese Flaky Scallion Pancake Production Line

TY-3168

Spring onion pie machine

To make machine-made spring onion pies close to manual-made one, we reform dough rolling and stretching mechanisms to get up to more layers and thin dough sheets for flaky scallion pancakes. Sprinkle oil and scallions smoothly and well mixed, you would getten better and more stable quality and higher production capacity of these spring onion lacha pastry pies than hand made ones.You will save human resources, get higher profit and become more competitive in the market.

The typical process of scallion pancake making like the following steps, has been integrated into an Automatic Intelligent Production Line and lowered the labour cost to the maximum.

1. Place the well-mixed dough (around 100KG) in once in the Dough Divider, then it leads the dough go through the Sheeting System in order; so that it decrease manually dough refill

2. After passing through first Dough Feeder, the continuous dough band then passing through 4 Pressing Wheels without damaging the dough and it is rolled into about 1 mm thickness dough sheet

3. Then the dough sheet goes through Stretch Mechanism, it becomes the 0.6 ~0.8 mm thin pastry

4. The thin sheet then passed through the Forming Conveyor in the later section, and it is automatically oiled, rolled in chopped green onion

5. A special cutting mechanism cuts the thin dough roll with well-covered shallots inside in required weight/length

6. The thin shallot rolls are rolled into a snail shape by special manual method or automatic rolling-up devices, and then go through Proofing section by manual placing or via Proofing Conveyor System

7. It finally might be feed in TY-788 Pressing & Filming Machine manually or automatically to form pieces of pancake

8. The Automatic Box Dropping System might be integrated to move the Stacking pancakes to the Automatic Packaging Machine directly, which implements a fully Automatic Production Line

Specification

- Size: L13,900 x D950 x H2,300mm

- Power: 220V/380V/415V, 3 Phase, 50/60Hz, 12HP

- Weight: 2100 Kgs

- Capacity: 2,100~5,000pcs/hr

- Products Range: 50gm~150gm/pc

Manufacture Product

- Flaky scallion pancake, filo, lacha paratha, thin dough sheet food, Burek

Training and service

Our professional training and after sale service group will teach you how to use the machine in the short time and supply sufficient information afterward.

- Movies

- Photo Gallery

- Related Catalogue

- Related Products

Automatic Puff Pastry Machine

TY-3000M

TY-3000M Puff pastry machine produce layered puff pastry sheets automatically with satellite...

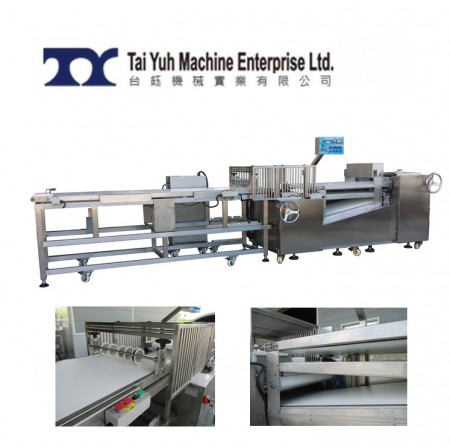

DetailsParatha pressing Machine

TY-788

It would save much of your time using machine to press pancakes instead of hand make.Put dough...

DetailsContinuous Dough Sheeter(Folding Type)

TY-598

TY-598 Dough roller machine can process 20-30kg of dough at once and folding,rolling the dough...

DetailsContinuous Dough Sheeter

TY-535

TY-535 Continuous dough sheeter can roll the dough sheet of buns and bread. The process of dough...

DetailsDough Divider

TY-03G

A large amount of dough can be directly poured into the machine for automatic cutting and shaping,...

Details

Chinese Flaky Scallion Pancake Production Line - Spring onion pie machine | Manufacturer of Stuffing Machines | Food Processing Machinery | Tai Yuh

Based in Taiwan for 30 years, Tai Yuh Machine Enterprise Ltd. / Best Food & Pastry Machinery Co., Ltd. has been a food machine manufacturer that is specialized in developing food processing machines with multipurpose. Their main products, include Chinese Flaky Scallion Pancake Production Line, food processing machinery for pancake and puff pastry, paratha and puri, pizz and calzone, and all kinds of ethnic food.

Tai Yuh was founded in 1993, is specialized in manufacture and design series of high quality and efficient food stuffing and forming machines, also the relative equipments. Tai Yuh is a professional frozen and food making machinery manufactory, like bakery, roti, paratha, dumpling, curry puff, lacha pratha, spring roll, samosa pastry, pizza base, bread and rolls making machine.

Tai Yuh has been providing high-quality bakery equipment since 1993, both with advanced technology and 30 years of experience, Tai Yuh ensures each customer's demands are met.