Automatic Intelligent Thin Pastry Production Line is coming

We launched Automatic Scallion Pancake Forming Machine since 2007. It has made the output pancake products keep stable and homogenized quality to decrease the waste and improve the capacity effectively. Furthermore, we continuously reform dough rolling and stretching mechanisms to get up to more layers and thin dough sheets for flaky scallion pancakes and make the taste similar to the handmade ones.

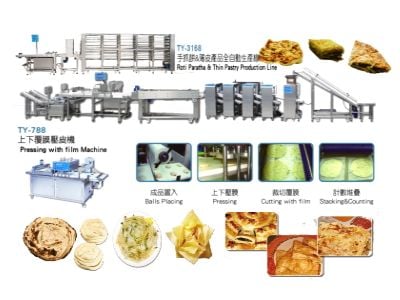

The typical process of scallion pancake making like the following steps, has been integrated into an Automatic Intelligent Production Line and lowered the labour cost to the maximum.

1. Place the well-mixed dough (around 100KG) in once in the Dough Divider, then it leads the dough go through the Sheeting System in order; so that it decrease manually dough refill

2. After passing through first Dough Feeder, the continuous dough band then passing through 4 Pressing Wheels without damaging the dough and it is rolled into about 1 mm thickness dough sheet

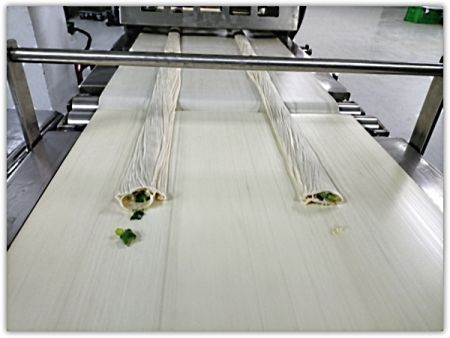

3. Then the dough sheet goes through Stretch Mechanism, it becomes the 0.6 ~0.8 mm thin pastry

4. The thin sheet then passed through the Forming Conveyor in the later section, and it is automatically oiled, rolled in chopped green onion

5. a special Cutting mechanism cuts the thin dough roll with well-covered shallots inside in required weight/length

6. The thin shallot rolls are rolled into a snail shape by special manual method or automatic rolling-up devices, and then go through Proofing section by manual placing or via Proofing Conveyor System

7. It finally might be feed in TY-788 Pressing & Filming Machine manually or automatically to form pieces of pancake

8. The Automatic Box Dropping System might be integrated to move the Stacking pancakes to the Automatic Packaging Machine directly, which implements a fully Automatic Production Line

Automatic Intelligent Thin Pastry Production Line is coming | Top Steamed Bun Machine for Commercial Kitchens and Bakeries

Based in Taiwan and established in 1993, Tai Yuh Machine Enterprise Ltd. specializes in manufacturing high-quality food processing machinery. Their product range includes steamed bun machines, stuffed bread making machines, dumpling machines, puff pastry machines, and tortilla/chapati making lines. Renowned for their innovative design and efficiency, Tai Yuh's machines are ideal for commercial and industrial food production, catering to international markets with reliable and customized solutions.

Tai Yuh offers a comprehensive one-stop manufacturing service, providing end-to-end solutions from design to production. With a global reach, their machines have been sold to over 20 countries, establishing a strong international presence and reputation for excellence in food processing equipment.

Tai Yuh has been providing high-quality food stuffing and forming machines, alongside related equipment since 1993. With advanced technology and 30 years of experience, Tai Yuh ensures each customer's demands are met.